Tible

Tible is a horizontal cable anchor for steel pile quay walls. Since started sale in 1971, TIBLE has been used without changing the basic structure and used for a considerable number of worldwide projects.

Tible is a horizontal cable anchor for steel pile quay walls. Since started sale in 1971, TIBLE has been used without changing the basic structure and used for a considerable number of worldwide projects.

Advantage

Wide range of product lines

You can decide the best reasonable cable within 18 types, F40T (387kN) – F600T (5819kN).

Light weight

TIBLE made form high strength steel PC strands is lighter weight than a tie rod.

Durability

Main cable is coated with enough thick high density polyethylene and include anti-rust oil.

Sleeve as an anchorage shuts PC strand away from external environment and has enough waterproofness.

Flexibility of cable effective against bending stress by earth pressure.

Workability

Pre-assembled cable reduces process of assembling, installing and support timbers.

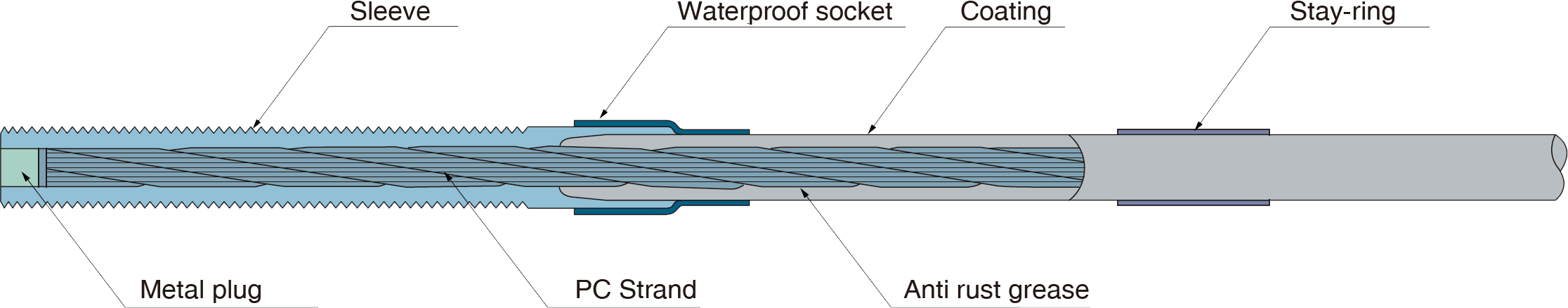

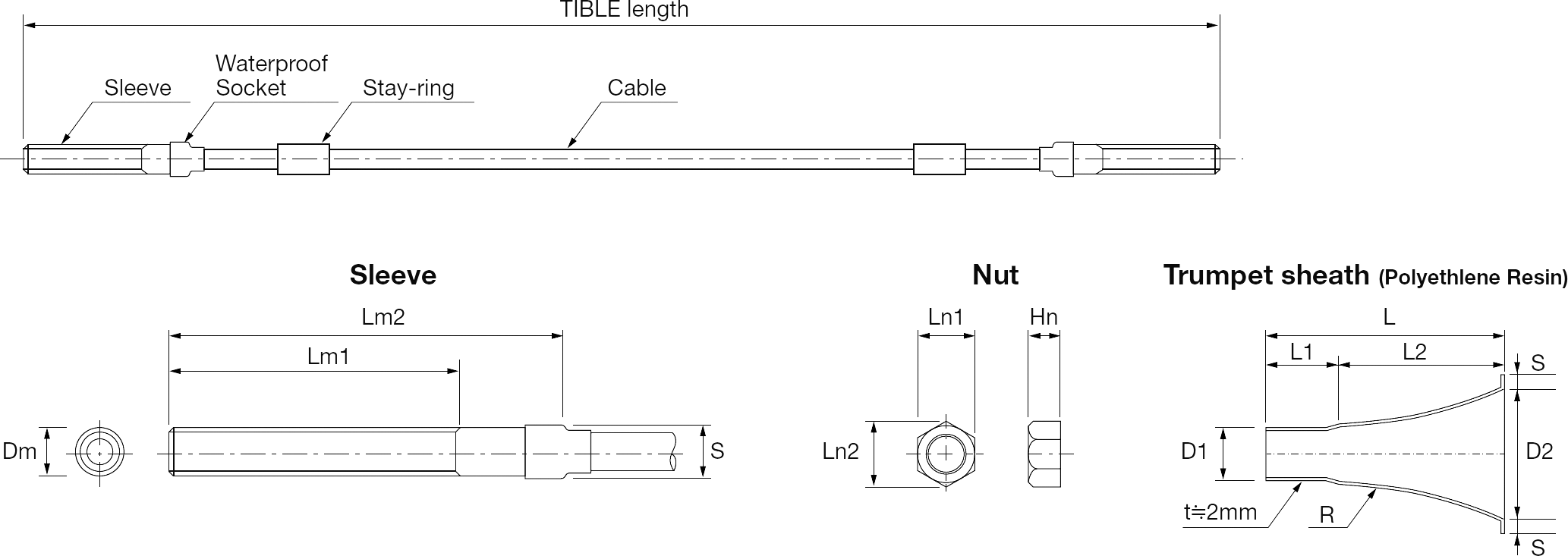

TIBLE Structure

| Item | Material |

|---|---|

| PC Strand | JIS G 3536 Steel wires and strands for prestressed concrete or Enhanced high strength PC strands |

| Sleeve | JIS G 4053 Low-alloyed steels for machine structural use |

| Coating | High density polyethylene resin |

| Anti rust grease | Lubricating grease including corrosion inhibitor |

| Metal plug | JIS G 3123 Cold finished carbon and alloy steel bars or JIS 4051 Carbon steels for machine structural use |

| Waterproof socket | High density polyethylene resin or Heat shrink tube |

| Stay-ring | PVC pipe |

Product data

| Type | F40T | F50T | F60T | F70T | F100T | F110T | F130T | F170T | F190T | F200T | F230T | F270T | F310T | F330T | F360T | F400T | F500T | F600T | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PC Strand | 1x Φ17.8 |

1x Φ20.3 |

1x Φ21.8 |

7x Φ9.5 |

7x Φ11.1 |

7x Φ12.4 |

7x Φ12.7 |

7x Φ15.2 |

7x Φ15.2 |

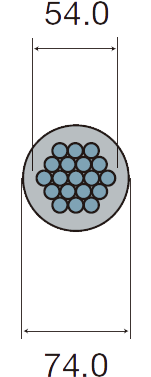

19x Φ9.5 |

19x Φ10.8 |

19x Φ11.1 |

19x Φ12.4 |

19x Φ12.4 |

19x Φ12.7 |

19x Φ12.7 |

19x Φ15.2 |

19x Φ15.2 |

|

| GRADE | 1860 | 1860 | 1860 | 1860 | 1860 | 1720 | 1860 | 1720 | 1860 | 1860 | 1720 | 1860 | 1720 | 1860 | 1860 | 2300 | 1860 | 2300 | |

| Area (mm²) | 208.4 | 270.9 | 312.9 | 383.9 | 519.3 | 650.3 | 691.0 | 970.9 | 970.9 | 1042.0 | 1323.9 | 1409.6 | 1765.1 | 1765.1 | 1875.5 | 1875.5 | 2635.3 | 2635.3 | |

| Weight (kg/m) |

Strand | 1.65 | 2.15 | 2.48 | 3.04 | 4.09 | 5.13 | 5.45 | 7.75 | 7.75 | 8.77 | 11.10 | 11.78 | 14.80 | 14.80 | 15.70 | 15.70 | 20.96 | 20.96 |

| Strand + Coating | 1.95 | 2.49 | 2.84 | 3.65 | 4.92 | 6.11 | 6.54 | 9.82 | 9.82 | 10.47 | 13.47 | 14.10 | 17.55 | 17.55 | 18.53 | 18.53 | 24.62 | 24.62 | |

| Tensile Strength (kN/mm²) | 387 | 495 | 573 | 714 | 966 | 1120 | 1281 | 1680 | 1827 | 1938 | 2280 | 2622 | 3040 | 3287 | 3477 | 4141 | 4761 | 5819 | |

| Yield Strenrth (kN/mm²) | 330 | 422 | 495 | 608 | 826 | 952 | 1092 | 1428 | 1554 | 1649 | 1938 | 2242 | 2584 | 2793 | 2964 | 3667 | 4178 | 5149 | |

| Cable section (mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Sleeve | Dm | 42 | 48 | 50 | 55.4 | 62 | 68 | 68 | 78 | 78 | 82 | 90 | 94 | 103 | 103 | 110 | 110 | 140 | 140 |

| Lm1 | 280 | 295 | 300 | 320 | 390 | 440 | 490 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Lm2 | 370 | 385 | 390 | 410 | 485 | 530 | 580 | 675 | 675 | 675 | 710 | 730 | 765 | 765 | 785 | 800 | 1250 | 1250 | |

| S | 52 | 58 | 60 | 67 | 73 | 78 | 78 | 90 | 90 | 92 | 102 | 105 | 113 | 113 | 122 | 122 | 144 | 144 | |

| Weight(kg) | 3.4 | 3.9 | 5.0 | 6.3 | 8.9 | 11.5 | 12.2 | 18.8 | 18.8 | 20.0 | 24.7 | 28.2 | 35.5 | 35.5 | 42.7 | 43.0 | 106.5 | 121.3 | |

| Nut | Ln1 | 63 | 75 | 75 | 82 | 93 | 97 | 97 | 115 | 115 | 120 | 130 | 135 | 150 | 150 | 155 | 171 | 195 | 208 |

| Ln2 | 72.7 | 86.6 | 86.6 | 94.7 | 107.4 | 112.0 | 112.0 | 132.8 | 132.8 | 138.6 | 150.1 | 155.9 | 173.2 | 173.2 | 179.0 | 197.5 | 225.2 | 240.2 | |

| Hn | 34 | 45 | 45 | 45 | 60 | 60 | 60 | 63 | 63 | 66 | 69 | 75 | 80 | 80 | 92 | 102 | 112 | 114 | |

| Weight(kg) | 0.6 | 1.1 | 1.1 | 1.2 | 1.9 | 2.0 | 2.0 | 3.0 | 3.0 | 3.5 | 4.7 | 5.2 | 7.3 | 7.3 | 8.0 | 12.7 | 15.8 | 19.8 | |

| Trumpet sheath | D1 | 27 | 37 | 37 | 40 | 45 | 50 | 50 | 65 | 65 | 65 | 77 | 77 | 90 | 90 | 90 | 90 | 116 | 116 |

| D2 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 180 | 180 | 180 | 180 | 180 | 185 | 185 | 185 | 185 | 214 | 214 | |

| S | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

| L | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 320 | 320 | 320 | 320 | 320 | 330 | 330 | 330 | 330 | 330 | 330 | |